Future-Proof Supply Chains

Boxbot

by supercharging productivity, maximizing throughput,

and unlocking intelligent applications.

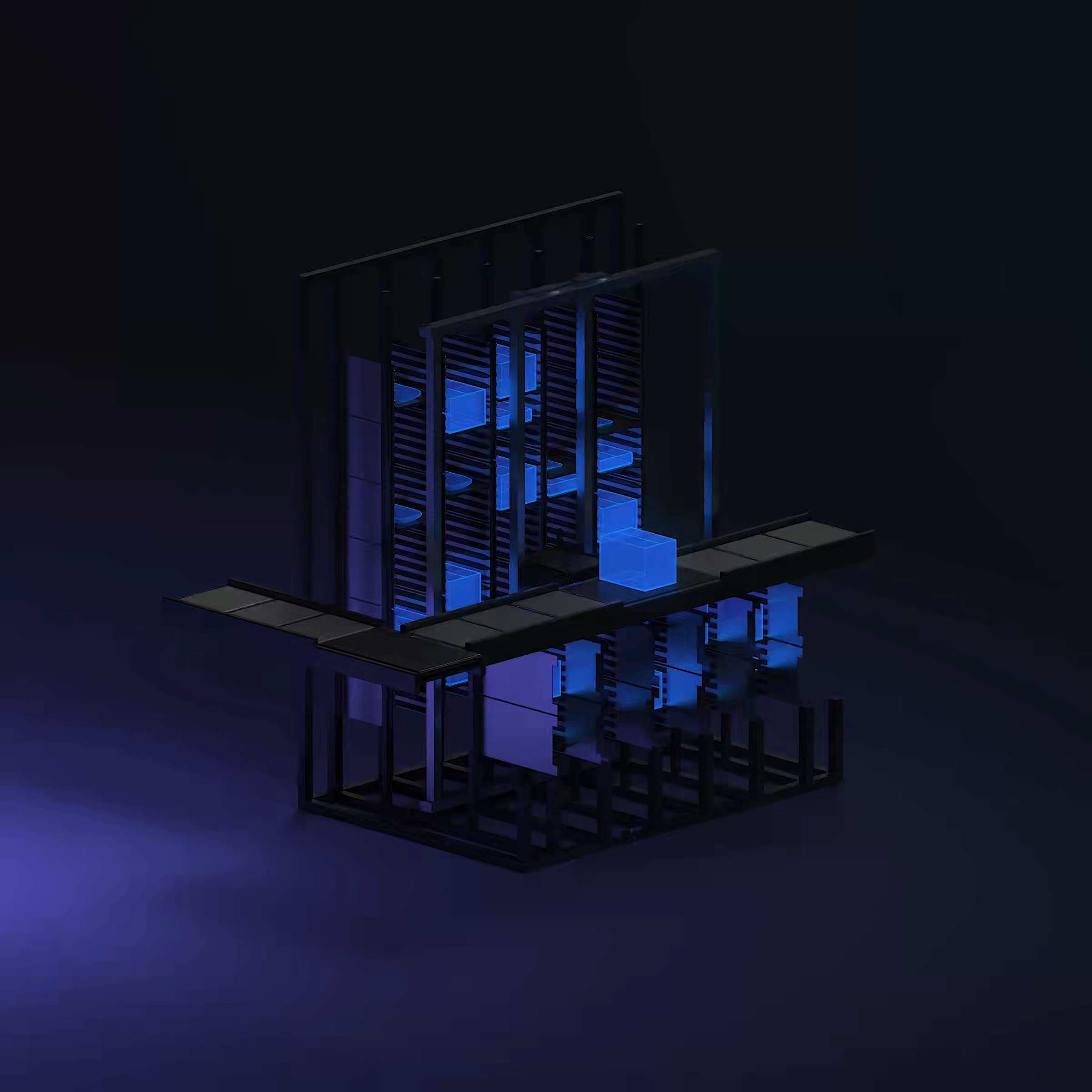

Dynamic Storage

Platform

Hands-Free Load/Unload

Variable Item Sizes & Weights

- Multiple storage tray dimensions

- Variable height storage based on item size

Robust & Fault-Tolerant Design

- Modular gantry

- No single point of failure

- Ease of maintenance and accessibility

Flexible Applications

Last Mile Delivery Stations

Streamline vehicle loading, order management, and wave dispatch

2X

Vehicle loading speed

Air Cargo / Bonded Storage

Automate inbound/outbound storage and inspections

20s

Inspect Retrieval Time

Group, sequence, and sort items in cross docks for optimal pallet building and dispatch

Cross Dock Buffering

3x

Pallet Building Efficiency

Automated Counter

On-demand single item retrieval in industrial or public-facing areas

Item Retrieval

15s

Scalable Platform

The Boxbot System is flexible, customizable, modular, and uses standard components — equally suited for either greenfield or highly constrained brownfield deployments.- Modules are configured with a unique length and height

- Modules are connected together to fit any physical space and application

2X

99.9%

Storage Density

Uptime

Productivity Improvement

80%

15Y+

System Lifespan

Intelligence

Next Generation Smart Facilities & Networks

System Intelligence

The Boxbot System uses machine learning to adapt to its environment and improve over time.

- Modules work together to dynamically optimize system storage capacity and throughput

- Full stack sensor fusion provides early error detection and recovery

Future-Proof Facilities

Boxbot enables facilities to improve over time and digitally scale operations.- Wave based dispatch to maximize throughput in existing footprint

- Sequencing and batching for pallet building and vehicle loading

- Productivity maximization by smoothing bursty labor requirements

Network Optimization

Boxbot unlocks network-level applications that transform supply chain economics.- Volume smoothing and load balancing

- Merge-in-transit of split shipments across facilities

- Synthetic density generation for last mile delivery

Leaders

“

Carriers have expanded their network capacities aggressively during the hypergrowth phase of e-commerce ... The next phase will be about using automation to enable volume growth through higher productivity, especially as the lasting impact of labor shortages and inflation are acutely felt.

”

“

I’ve seen firsthand that there is a massive opportunity to shift manual processes to machine-enabled smart and efficient solutions leveraging software and hardware. Boxbot’s one-stop solution is a versatile and integrated system that works across a variety of areas in the supply chain.

”

Investors

FAQ

-

Cartons, Cases, Totes, and other items can be stored on standard Boxbot trays.

Small polybags, letters, cylinders, bags, and other irregular objects can be handled by Boxbot once placed in totes.

The smallest accepted item is currently 6”x6”x1” and 1 lbs. The largest accepted item is currently 35”x24”x24” and 75 lbs.

-

Modules can be built up to 25’.

-

System throughput ranges from 250 PPH - 4,000+ PPH based on the number and size of modules that are added.

-

Any application where sub-unit load items are being handled, buffered, or stored can use the Boxbot System.

Boxbot excels when there is a need to individually handle cases or post-pack eaches, especially if there is a size or weight variation between items. This need is prevalent in the parcel delivery, 3PL, airport, industrial, and retail sectors.

The potential use cases in these and other industries are expansive.